Coatings

How Zinc Protects

Zinc-coated steel is one of the strongest construction materials in existence and has been used for centuries in the building of bridges, buildings, and other structures.

Options for Zinc Coatings

There are a variety of zinc coatings available. It is important that the correct zinc coating is specified to provide optimal performance under the exposure conditions to which the coating will be subjected.

Continuous Galvanizing

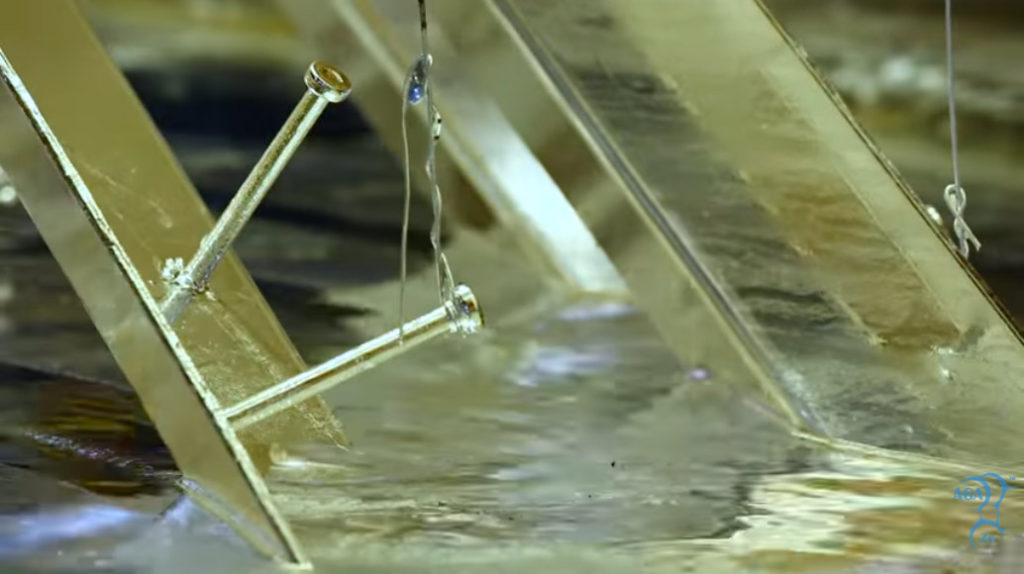

In the continuous hot-dip galvanizing process, steel is fed through cleaning and annealing sections before entering a molten zinc bath at speeds up to 200 meters per minute (650 feet/minute). As the steel exits the molten zinc bath, gas “knives” wipe off the excess coating from the steel sheet to control coating thickness. The steel then undergoes a series of mechanical or chemical treatments. Depending on customer requirements, the coated steel can be passivated, oiled and recoiled, or cut to length and palletized before shipment to the fabricator.

Continuously galvanized coatings are metallurgically bonded to the steel they protect. This ensures coating adhesion – critical for manufacturing processes that bend, stamp, roll or draw the steel into its final product shape.

Types of Products

Starting from high purity zinc, alloying elements can be added to produce galvanized coatings with different properties. The family of continuous galvanized coatings includes galvanized, electrogalvanized, galvanneal, Galvalume® and Galfan® coatings.

Galvanized

A pure zinc coating that is the standard continuous galvanized product typically used in building panels, steel framing, agricultural and automotive applications, as well as in numerous other functions. It has good surface finish and adhesion properties.

Electrogalvanized

Generally a pure zinc coating, although alloys (e.g. Zn-Fe, Zn-Ni) are available. Coating thickness is typically lower than for a galvanized product. Provides an ultra-smooth finish which is desirable for surface critical parts such as automotive exterior body panels.

Galvanneal

A zinc-iron alloy coating with improved paintability, weldability and drawability, Galvanneal is used in the automotive industry because of its improved manufacturing performance in models that use lighter and stronger grades of steel.

Galvalume®

A zinc-55% aluminum alloy coating with superior corrosion resistance for applications without severe forming. Widely used for painted and unpainted building panels and roofing and for higher temperature applications and heat-reflective components.

Galfan®

A zinc-5% aluminum coating with superior corrosion resistance when formed. Galfan coated steel is noted for its outstanding coating adhesion, making it ideal for deep drawn and “zero-thickness” bend applications.

Continuous Galvanizing Questions?

Should you have any technical inquiries or specific questions, please send us a message or visit our dedicated continuous galvanized sheet microsite. We encourage visitors to take advantage of the GalvInfo Library as many FAQ’s are answered there.

General Galvanizing

Also known as Hot Dip Galvanizing, After-Fabrication Galvanizing or Batch Galvanizing, refers to the galvanizing of fabricated or manufactured steel items. The fabricated steel article is cleaned and then dipped into a molten zinc bath, either on racks for small items or individually for large items.

Zinc coatings from this process are two to six times thicker than continuously galvanized coatings and can offer long term outdoor protection in most environments. This resistance can vary from 20 years in an industrial site to over a century in a rural environment.

General galvanizing provides fabricated steel items with excellent protection against corrosion. The nature of the immersion process provides good edge protection and complete coverage of the outer surface area as well as inner protection of hollow parts. In general, a zinc coating of at least 60-70 μm is applied.

The factory controlled galvanizing process is independent of weather and galvanizers are in virtually all areas of the world.

Video Series - Sustainable Galvanizing

Architects and designers discuss the selection of galvanized components in their projects.

|

Energy from Waste Plant in Suffolk - TSP

Galvanizers Association |

|

Steel Grating for Creative Labs - Edinburgh Sculpture Workshop

Galvanizers Association |

|

Architecture Archive and Avon Wildlife Trust Cabin

Galvanizers Association |

|

Steel Canopy in Netherlands - Almere Windhinders

Galvanizers Association |

|

Artisan Café Concept Includes Galvanised Steel

Galvanizers Association |

Thermal Spray/Metallizing

Zinc metallizing, or thermal spraying, is a process by which zinc wire, or powder, is fed into a spray gun, melted and sprayed onto a work piece. Melting is accomplished either by combustion in an oxygen-fuel gas flame, or by an electric arc that is created between two zinc wires. The resulting metallic coating is slightly porous with a lamella or layered structure. Metallized coatings can be applied at high thickness (100–200 μm) which makes them ideal for long-term corrosion protection.

Thermal sprayed Zn-based coatings are mainly zinc and aluminum coatings or their alloys (mostly Zn and Zn-15%Al coatings).

Thermal spraying is particularly suited to protecting articles which are too large to be dipped in the galvanizing bath. Another benefit of zinc thermal spraying is that, like zinc-rich paint, it can coat steel that is already installed.

thermal spray zinc coatings

Zinc-Rich Paint

By 1968, advancing corrosion of San Francisco’s iconinc Golden State Bridge sparked a program to remove the original lead based paint and replace it with an inorganic zinc silicate primer and acrylic topcoats. This process was completed in 1995.

Zinc-rich paint typically contains over 77% zinc in the dry film and benefits from the barrier and cathodic protection provided by zinc. They are classified as organic, or inorganic, depending on the binder used.

Mechanical Plating

This process is used primarily for small (<0.5kg) threaded work or other close tolerance items. The parts to be plated are tumbled together with zinc powder and glass beads in water. The tumbling action causes the glass beads to hammer the zinc onto the part.

This process eliminates the possibility of hydrogen embrittlement of high strength fasteners. Coating thickness is controlled by time and quantity of zinc powder added.

Sherardizing

A diffusion controlled process which produces a zinc iron alloy coating. Small fabricated articles are charged in a drum with zinc powder and sand. The drum is rotated at a temperature below the melting point of zinc, typically 380 ̊C, for up to 3 hours. Uniform, hard, abrasion resistant coatings can be formed on complex parts.