Life Cycle Assessment

LIFE CYCLE ASSESSMENT FOR ZINC

The first LCA for primary zinc was completed in 1998, and subsequently updated by IZA in 2007, 2014 and again in 2022. Each global update has expanded geographic and market representation for the primary zinc LCA.

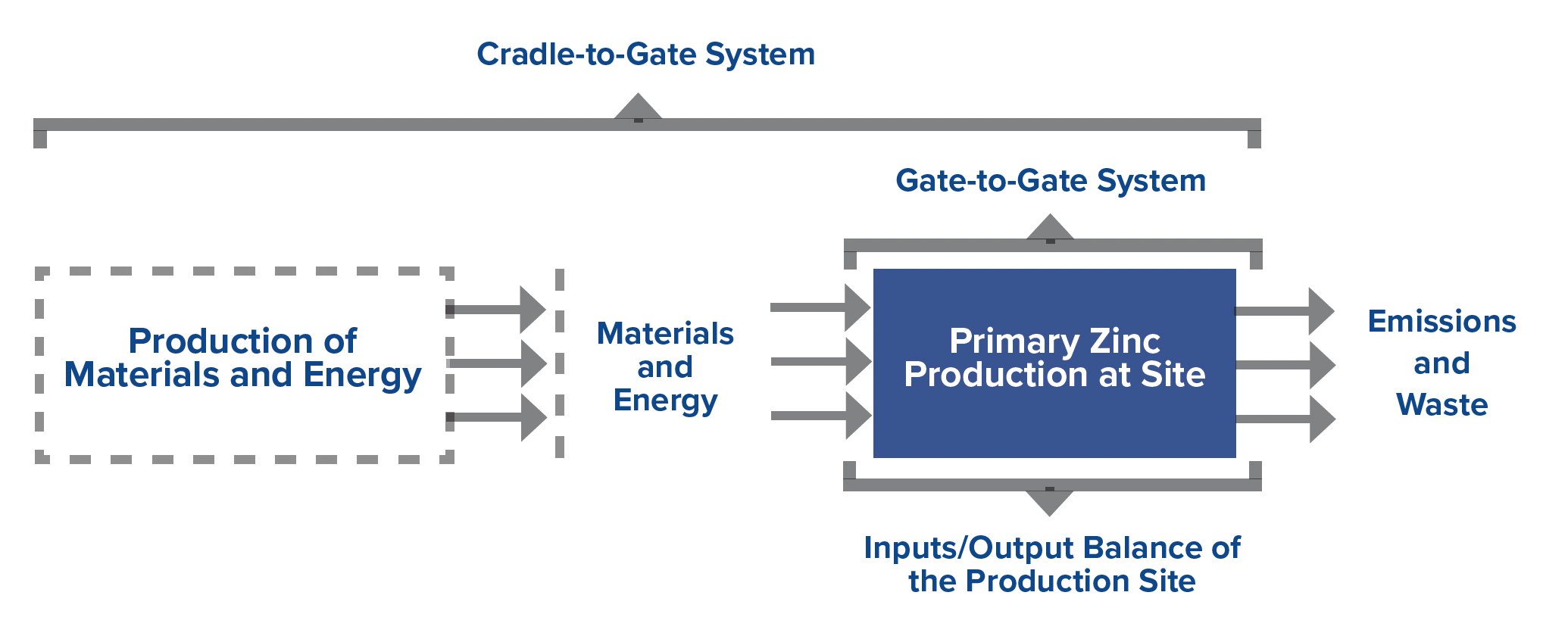

Life Cycle Assessment (LCA) is a decision-making tool to identify environmental burdens and evaluate the environmental consequences of a material, product, process, or service over its life cycle. This includes the impact on climate as Carbon Footprint (GWP) and the Water Footprint. For raw materials, this process encompasses cradle to gate (mine to refined metal). However, cradle-to-grave (mine to end of use) considerations for many products (galvanized steel applications, automobiles, utility poles, etc.) also require this basic information on raw materials.

By characterizing the environmental profile of refined zinc and zinc products, necessary information can be provided to stakeholders for use in life cycle management initiatives for corporations and public institutions.

LCA has been standardized by the International Organization for Standardization (ISO) and forms the conceptual basis for several management approaches and standards that consider the life cycle impacts of product systems.

IZA, supported by experts from Sphera, has completed the 2023 LCA update for special high-grade zinc based on 2021 industry data. Twenty-six mines and 23 smelters from all over the world participated in the 2023 update representing up to 30% of the global zinc demand. The full report is ISO-compliant and has been peer-reviewed by Anne L. Greig, Four Elements.

We are proud of providing designers, specifiers, and companies supplying zinc with the best available, high-quality industry average environmental footprint for special high-grade zinc. Our ambition is to make the global industry average life cycle assessment even more representative over time. Zinc mines, smelters, and Waelz kiln operators are invited to contact us (sgrund@zinc.org) to ensure their participation in the 2024 update and receive their company-specific benchmark report.

IZA Role in LCA

Increasingly the zinc industry is being asked to provide information to downstream users of zinc and zinc containing products on the environmental footprint of the materials it produces. Material specifiers and product engineers in key end-use markets such as construction and transportation are becoming more interested in selecting materials that have the best environmental profile while meeting traditional cost, quality and technical performance criteria.

Through regular surveys and Life Cycle Inventory updates from its members, the IZA LCA for primary zinc represents the most comprehensive environmental profile for zinc. The process requires documenting:

- Resource requirements (energy and non-energy.)

- Environmental releases from upstream operations (e.g. mining and refining) and downstream product use.

- Benefits of zinc for product durability and recyclability.

Benefits from zinc use occur when extending the life of galvanized steel products and utilizing secondary zinc to create new products.

Zinc Life Cycle Assessment by the Numbers

Global Impact

The current global LCA for primary zinc includes data from 26 mines and 23 smelters, which cover 2.5 Mt of zinc concentrate and 3.97 Mt of Special High-Grade Zinc, representing 20 and 29 % of global production, respectively

Improvements

When interpreting LCA data, today the focus lies on the carbon footprint which in LCA is expressed as Global Warming Potential (GWP). The Carbon Footprint for primary zinc production was calculated to be 3.89 kg CO2eq per kg SHG zinc at the global average.